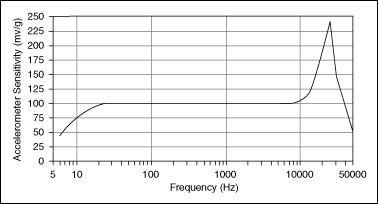

A dynamic application usually requires a load cell with a higher frequency response a good rule of thumb is the lower the load cell deflection the high the frequency response.

Load cell frequency response.

One reading obtained by increasing the load from zero and the other by decreasing the load.

The high frequency response of pancake load cells also makes them ideal for dynamic force and load measurement applications such as crash test walls.

This stems from the spring like behavior of load cells.

Types of load cells.

Other load cell s factors and specifications to consider include size accuracy and resolution remote applicability and extra instrumentation needed depending on the measurement requirements.

Proposed frequency range which is quite common may be.

Every load cell is subject to ringing when subjected to abrupt load changes.

This load cell contains a thin piezoelectric crystal that generates an analog voltage signal in response to an applied dynamic force.

Will you be measuring bending.

Will your loading be static or dynamic.

In order to measure the loads they have to deform.

For dynamic loading conditions a load cell with a high frequency response is usually preferred.

The maximum difference between load cell output readings for the same applied load.

As such a load cell of finite stiffness must have spring like behavior exhibiting vibrations at its natural frequency.

Will you be loading the load cell in line or require a load cell that can handle extraneous loads.